Technical Services

Casing Design

DETAILS

- Casing design verification/certification

- Load analysis and metallurgy selection

- Casing design optimization

- Salt loading design

- Casing wear studies

- Casing integrity verification for Worst Case Discharge (WCD) including design of mitigations

- BOEM Worst Case Discharge load analysis

Production and Well Integrity

DETAILS

- Conductor load analysis

- Production data analysis

- Well design check for drill stem testing (DST) and production loads – determination of design limited flow rate and/or duration

- Production hanger load analysis

- Wellhead movement analysis

- Wellhead, conductor and surface casing load and failure studies

- Annular Pressure Build-up (APB) analysis and design of mitigations burst disk and syntactic foam

- Annular pressure management

- Determination of operating limits (minimum and maximum)

- Production well failure analysis

- Injector well annulus pressure reduction

- Fracture load analysis

- Well abandonment design

Drilling Optimization

DETAILS

- Drillstring optimization and vibration analysis

- Data analysis – Torque and Drag, pressure, weight on bit, rpm etc.

- Well construction improvement – analysis of data to remove lost time

- ROP improvement during well construction using drilling data analytics

- Drilling procedures improvement g. optimization of tieback cementing, plug cementing

- Well design re-engineering for value proposition

- Wellbore optimization and lean profile

Well Construction Safety

DETAILS

- Risk identification and assessment e.g. well control, stuck pipe, lost circulation etc.

- Generation/assessment of risk barriers

- Tracking barrier effectiveness using data analytics

- Review of well construction procedures for barrier deficiencie

Drilling Feasibility Studies

DETAILS

- Torque and Drag analysis and well trajectory optimization

- Rig capacity (mechanical and hydraulic horse power)

- Hydraulics

- Drillstring optimization/ drill pipe and connection selection/critical speed analysis

- ECD prediction and control

- Friction loss simulations e.g. choke line friction pressure

- Casing and connections optimization for service loads/procurement

- Creation of Well Abandonment Plan (WAP)

Training

DETAILS

- Process safety and risk management in well construction

- Drilling optimization

- Basic drilling engineering

- Casing design

- Determination of well operating limit – well integrity

Drilling procedures development

DETAILS

- We provide clear and concise step by step program with clearly defined parameters

- Important decision points are highlighted.

- Simply flow chart when needed to reduce risk of human error.

Software development

DETAILS

With your data we can perform analysis to develop custom made equations to fit your operations-these can then be transformed into software for easy usability.

We are able to meet your training needs in the following subject matter:

- Process safety and risk management in well construction

- Drilling optimization

- Basic drilling engineering

- Casing design

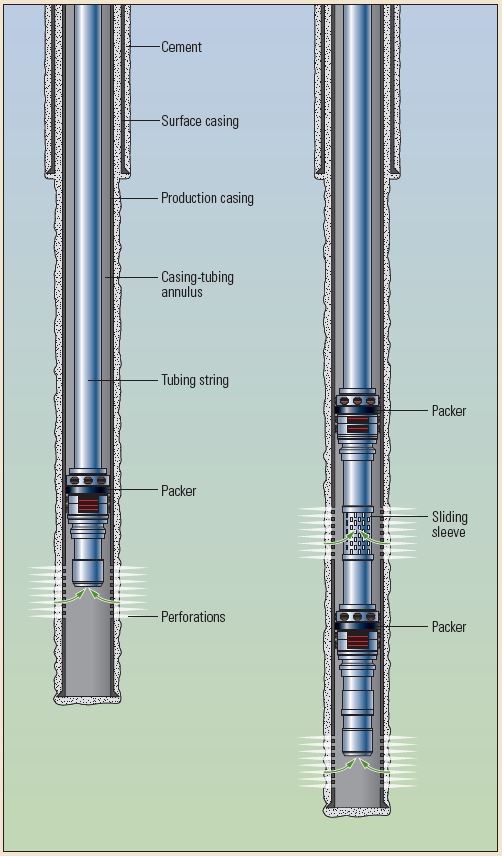

Our engineers are vast in the use of industry recognized software and also have significant operational experience to back it up thus providing ability to use standard software to build non-conventional models arising from well complexity.We are registered with the Texas Board of Professional Engineering and approved to provide engineering services.Well architecture is the frame work of well construction and drilling program, lots of issues could be avoided with optimum well architecture simple enough to drill but robust for the anticipated drilling and service loads.

Simplified List of Services

- Casing design – load analysis, metallurgy selection and casing design certification

- Drilling feasibility studies – hydraulics, torque and drag modeling, vibration analysis

- AFE preparation based on offset well analysis

- Wellhead movement analysis

- Risk analysis and barrier generation

- Conductor, surface casing and wellhead load analysis

- Drilling program preparation

- Wellbore design, lean profile and schematic preparation

- Producing well failure analysis

- Determination of well operating temperature and pressure limits for producers and injectors

- Injector well integrity check for annulus pressure depression

- Production modeling for well integrity – annulus pressure build up and maximum allowable pressures

- Fracturing load simulation

- Burst disk and syntactic foam design

- Production data analysis

- Salt loading design

- Well integrity consulting

- Well capability assessment for worst case discharge

- BOEM Worst Case Discharge spreadsheet completion

- Well abandonment design

- Real-time data analysis for well construction cost optimization

- Well design re-engineering for value proposition

- Expert witness

Drilling & Well Engineering Consultants Provide!

We are registered with the Texas Board of Professional Engineering and approved to provide engineering services.

Well architecture is the frame work of well construction and drilling program, lots of issues could be avoided with optimum well architecture simple enough to drill but robust for the anticipated drilling and service loads.

CONTACT US

LOCATIOIN

Houston, TX 77077

USA